- Home

-

Products

» Bathrive-V6 furnace temperature tester » Bathrive-SU furnace temperature tester » Bathrive-FBT furnace temperature tester » Bathrive-GX wireless furnace temperature tester » Bathrive-TMS online furnace temperature monitoring system » Slim Series Wireless Furnace Temperature Tester » 2D solder paste thickness gauge » 3D solder paste thickness gauge » High temperature insulation box » Auxiliary temperature measurement device » Oxygen concentration analyzer

- About Us

- News

- Case Video

- Cooperative partner

- Contact us

-

English

English

Products

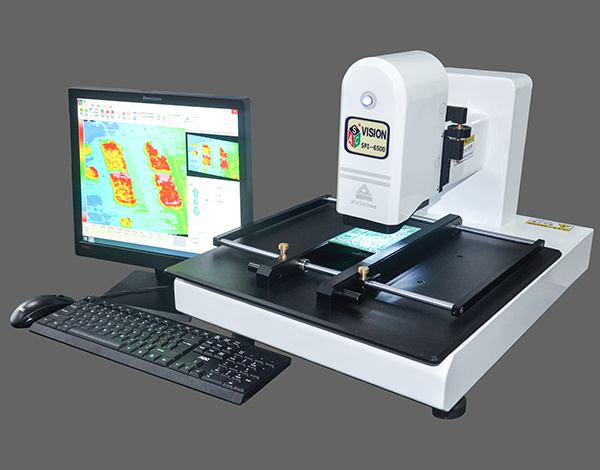

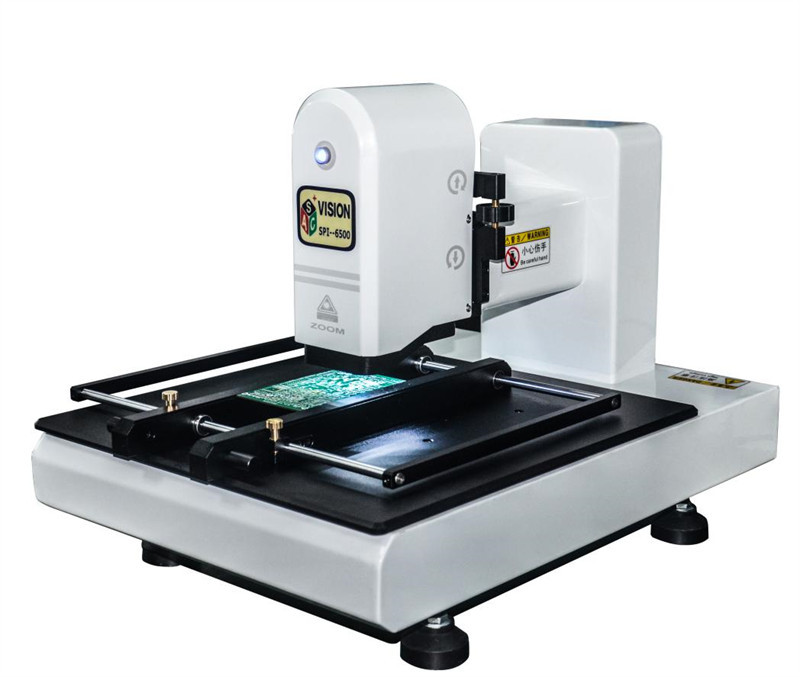

3D solder paste thickness tester

Category: 3D solder paste thickness gauge

Commodity name: 3D solder paste thickness tester Commodity ID: 3D SPI 6500 Type: semi-automatic 3D mode, manual 3D mode1. Product functions1. Friendly programming interface.2. A variety of measurement methods3. The scanning spacing is adjustable4. Image 3D simulation function5. Independent 3D dynamic observer6. Powerful SPC function7. It can measure the thickness of silk screen printing and copper sheetSecond, product features1. The original high-definition color camera imported from Germany is adopted to ensure the high precision and high stability of the test.2. The use of military-grade secondary las

- DESCRIPTION

- Commodity name: 3D solder paste thickness tester

- Commodity ID: 3D SPI 6500

Type: semi-automatic 3D mode, manual 3D mode

1. Product functions

1. Friendly programming interface.

2. A variety of measurement methods

3. The scanning spacing is adjustable

4. Image 3D simulation function

5. Independent 3D dynamic observer

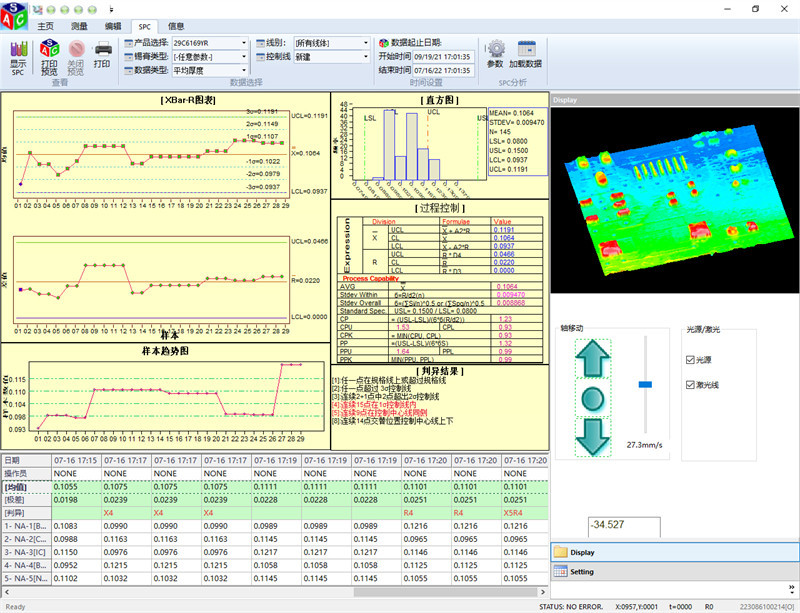

6. Powerful SPC function

7. It can measure the thickness of silk screen printing and copper sheet

Second, product features

1. The original high-definition color camera imported from Germany is adopted to ensure the high precision and high stability of the test.

2. The use of military-grade secondary laser, less interference by external environmental light source, more stable and longer life.

3. Using flexible hardware design, light source, laser and camera, different colors of PCB board can be tested.

4. The software analysis conditions are based on the database, and the early warning function is realized according to the analysis conditions, which is intuitive and easy to understand.

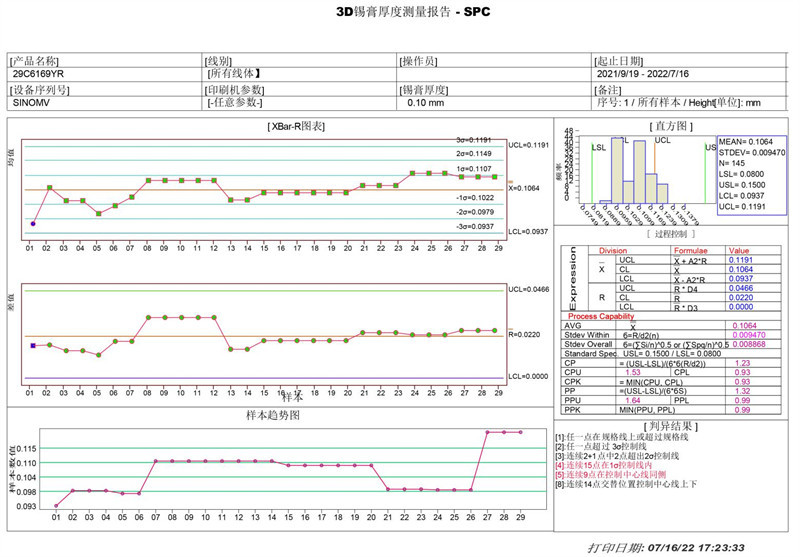

5. Powerful report analysis function, automatically generate R-Chart, X-Bar, automatically calculate CPK.

6. Export detailed and complete SPC reports to completely avoid the drawbacks of handwritten reports.

7. The software adopts a simple and practical concept, focusing on the high-precision design of the test, and the repeatability of the correction block reaches plus or minus 0.001mm.

Third, product parameters

1. Brand: ASC

2. Model: SPI-6500

3. Software language: Chinese Simplified, English

4. Application range: solder paste, red glue, BGA, FPC, CSP, etc

5. Measurement items: thickness, area, volume, plane distance

6. PCB deformation correction: PCB tilt angle is automatically calculated and automatically corrected

7. Focus mode: manual focus

8. Lighting source: white LED module

9. Measurement light source: 650nm low-power red laser module

10. Measurement principle: laser 3-angle function method measurement

11.Y axis automatic moving range: 60mm

12. Precision resolution: 0.1 micron

13. Field of view (FOV): 15*12 (W*H) mm

14. Scanning step: minimum 5 microns (5 microns/10 microns/15 microns/20 microns)

15. PCB size: 400*400mm (special size can be customized)

16. Repeatable measurement accuracy: less than 1 micron

17. Volume repeatability: less than 1%

18. Area repeatability: less than 1%

19. Allowable PCB thickness: 1~10mm

20. Maximum measurement height: 4mm

21. Image resolution: 300 million

22. Measurement speed: up to 250 frames per second

23.3D display mode: point array display, line array display, rendering display, can be rotated at any angle

24. Measurement method: automatic full-screen measurement, automatic measurement by frame selection, manual measurement by frame selection

25. SPC analysis: average, maximum, minimum, X-Bar&R plot analysis, histogram analysis &Ca/Cp/Cpk output, etc. Sigma judged automatically

26. Process control: production line, time, printing materials, solder paste data, steel mesh data,

27. Operating system: Windows 7 or above

28. Computer system: dual-core 2G or more, 2G memory, PCI slot, USB interface 3, 17-inch LCD monitor

29. Equipment power supply: 220V/50/60HZ

30. Equipment power consumption: 300W

31. Equipment weight: 45kg

32. Dimensions: L*W*H(400mm*550mm*360mm)

4. Product pictures

Instrument master diagram

Convenient and adjustable PCB fixture

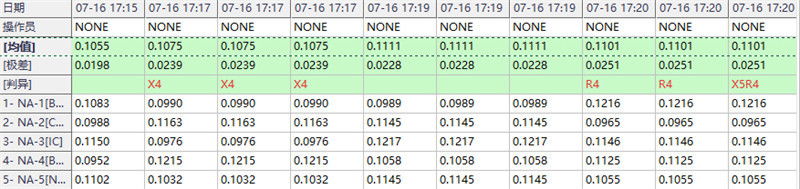

SPC data analysis interface

SPC measurement report

The main interface of the software

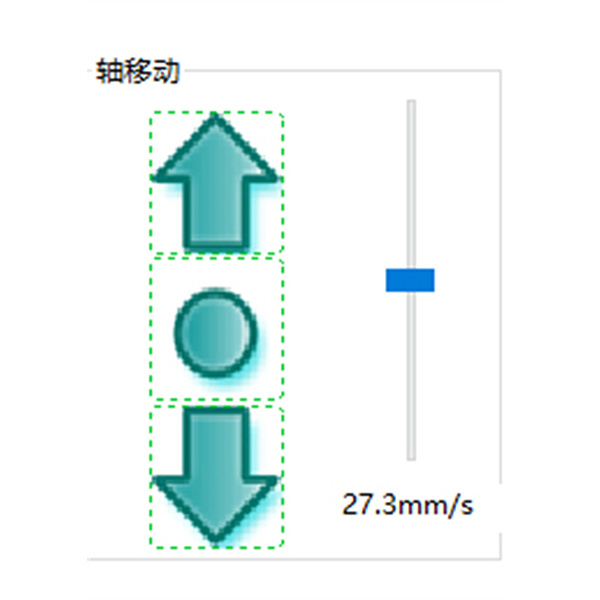

Z-axis motion button/focus

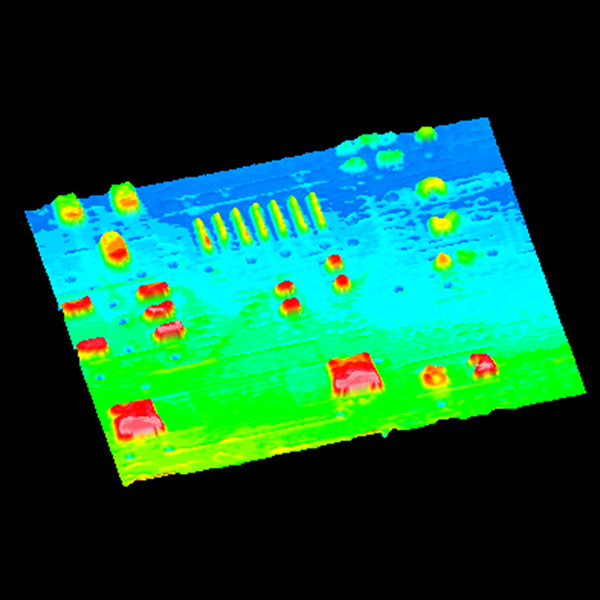

3D scan of the physical image

Measurement data