- Home

-

Products

» Bathrive-V6 furnace temperature tester » Bathrive-SU furnace temperature tester » Bathrive-FBT furnace temperature tester » Bathrive-GX wireless furnace temperature tester » Bathrive-TMS online furnace temperature monitoring system » Slim Series Wireless Furnace Temperature Tester » 2D solder paste thickness gauge » 3D solder paste thickness gauge » High temperature insulation box » Auxiliary temperature measurement device » Oxygen concentration analyzer

- About Us

- News

- Case Video

- Cooperative partner

- Contact us

-

English

English

Products

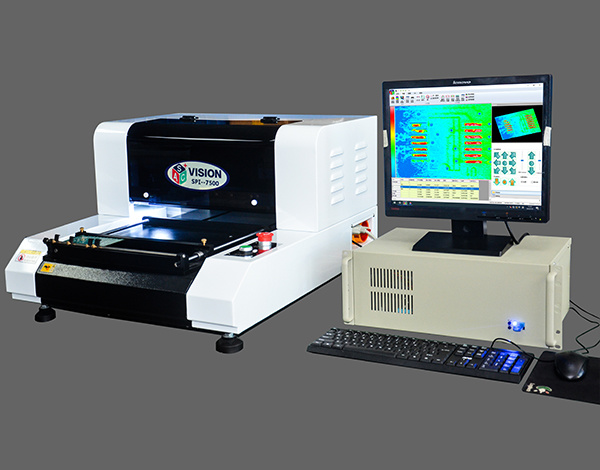

3D solder paste thickness gauge

Category: 3D solder paste thickness gauge

Commodity name:3D solder paste thickness gauge Commodity ID: ASC SPI-7500 Type: Fully automatic 3D mode, semi-automatic 3D mode, manual 3D mode1. Product functions1. Fast programming, friendly programming interface2. Multiple ways to measure3. Truly one-click measurement4. Bafang movement button, one-key focus5. The scanning spacing is adjustable6. Solder paste 3D simulation function7. Powerful SPC function8. MARK deviation is automatically corrected9. One-click back to the center of the screen functionSecond, product featuresThe automatic 3D solder paste thickness tester can pass the automatic movement

- DESCRIPTION

- Commodity name:3D solder paste thickness gauge

- Commodity ID: ASC SPI-7500

Type: Fully automatic 3D mode, semi-automatic 3D mode, manual 3D mode

1. Product functions

1. Fast programming, friendly programming interface

2. Multiple ways to measure

3. Truly one-click measurement

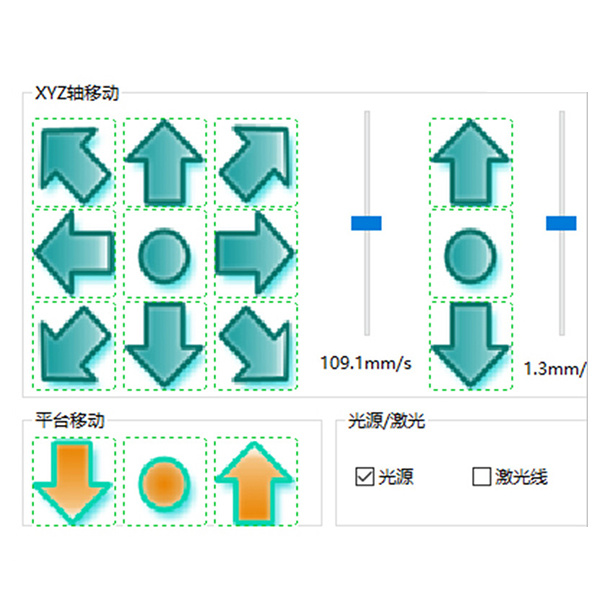

4. Bafang movement button, one-key focus

5. The scanning spacing is adjustable

6. Solder paste 3D simulation function

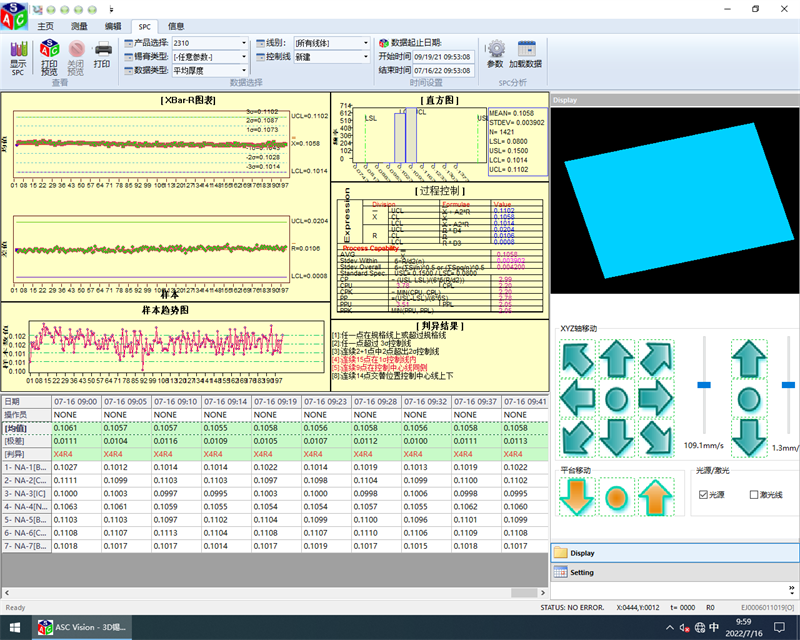

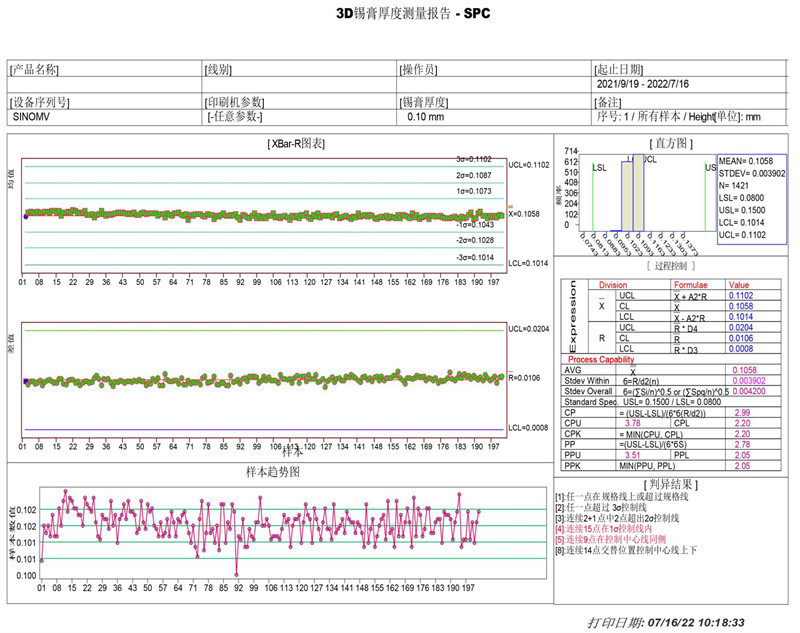

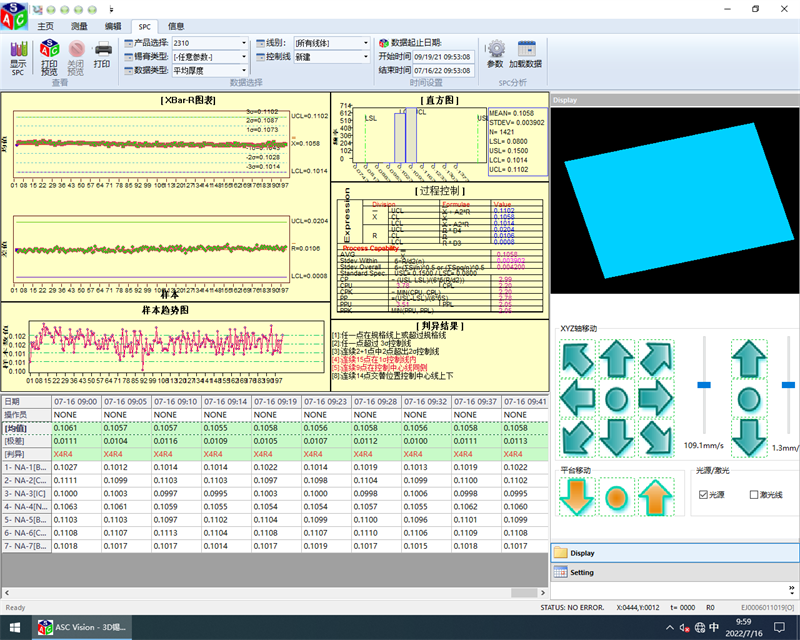

7. Powerful SPC function

8. MARK deviation is automatically corrected

9. One-click back to the center of the screen function

Second, product features

The automatic 3D solder paste thickness tester can pass the automatic movement of the XY platform, the Z axis automatic focusing, and cooperate with the laser to scan the solder paste printed on the pad, obtain the 3D data of each FOV, and can also be used to measure the average thickness of the solder paste on the entire FOV pad, so that the quality of solder paste printing becomes controllable

[Features]

1. Programmable measurement of several areas, automatic focusing at different test points, to overcome the error caused by plate deformation;

2. Automatically find the inspection position and correct the offset through PCB MARK;

3. Measurement mode: fully automatic, automatic mobile manual measurement, manual mobile manual measurement;

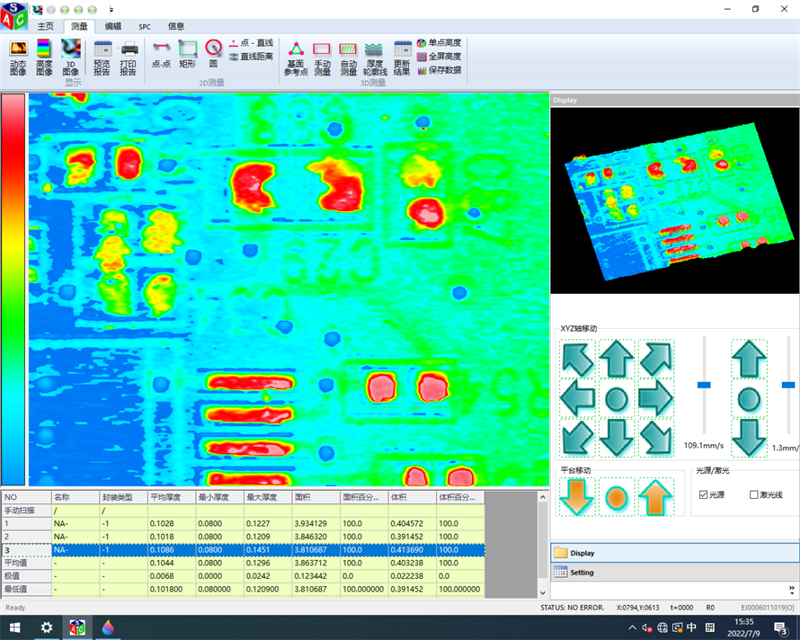

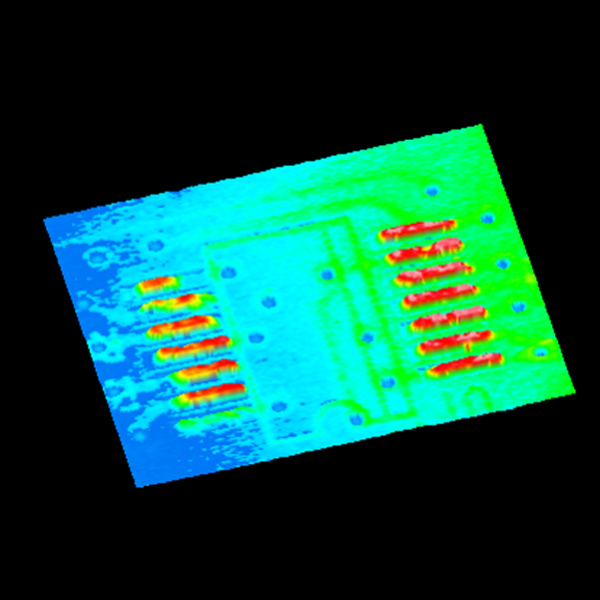

4. Solder paste 3D simulation drawing, reproduce the real shape of solder paste;

5. Adopt 3-axis automatic movement and focusing, automatically compensate and correct the warpage deformation of the substrate, and obtain the accurate height of the solder paste;

6. High-speed and high-resolution camera, high precision, powerful SPC data statistical analysis;

7. SIGMA automatic discrimination function, so that your operators have the ability to judge the quality of the solder paste printing process in real time;

8. Automatically generate CP, CPK, X-BAR, R-CHART, SIGMA column chart, trend chart, control chart, etc.

9. 2D auxiliary measurement, distance between two points, area size, etc.;

10. The list of measurement result data is automatically saved and SPC report is generated.

Third, product parameters

1. Application range: solder paste. Red gum. BGA. FPC. CSP

2. Measurement item: thickness. Area. Volume.3D shape, plane distance

3. Measurement principle: laser 3-angle function method measurement

4. Software language: Chinese/English

5. Lighting source: white high-brightness LED

6. Measurement light source: red laser module

7. X/Y moving range: standard 350mm*340mm (larger moving size can be specially customized)

8. Measurement method: automatic full-screen measurement. Automatic measurement by frame selection. Manual measurement is selected in the box

9. Field of view: 12mm*15mm

10. Camera pixels: 300 million / field of view

11. Maximum resolution: 0.1um

12. Scanning distance: 5 um/10 um/15 um/20 um

13. Repeated measurement accuracy: height less than 1um, area <1%, volume <1%

14. Magnification: 50X

15. Maximum measurable height: 5 mm

16. Maximum measurement speed: 250Profiles/s

17. 3D mode: rendering. Face. Line. Point 3 different 3D simulations, zoomable. revolve

18. SPC software: production line data, printing data, solder paste data, steel mesh data, measurement results independent analysis, X-Bar&R diagram analysis, histogram analysis &Ca/Cp/Cpk output, Sigma automatic judgment

19. Operating system: Windows 7

20. Computer system: dual-core P4, 2G memory, 17-inch LCD

21. Power supply: 220V 50/60Hz

22. Maximum power consumption: 500W

23. Weight: about 85KG

24. Dimensions: L*W*H (700mm*800mm*400mm)

4. Product pictures

Instrument master diagram

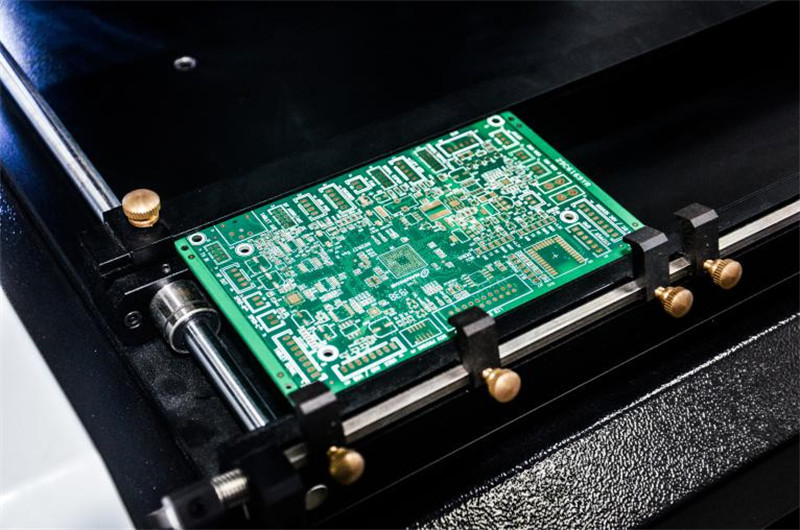

PCB automatic clamping

True one-click measurement

SPC data analysis interface

SPC measurement report

The main interface of the software

Bafang motion button/one-key focus

3D scan of the physical image

Measurement data